Oxford Instruments Plasma Technology represents a pivotal advancement in the world of plasma science and applications. The company’s innovation in plasma technology has contributed to numerous fields, from semiconductor manufacturing to material science and beyond. This article will delve into the various aspects of Oxford Instruments Plasma Technology, its capabilities, and its impact on industries worldwide.

What is Oxford Instruments Plasma Technology?

Oxford Instruments Plasma Technology is a division within Oxford Instruments, a company known for pioneering scientific instruments and providing cutting-edge solutions to research and industrial challenges. Plasma technology, particularly in the context of Oxford Instruments, refers to the application of highly controlled plasma environments in various scientific and industrial processes. Plasma, often referred to as the “fourth state of matter,” plays a crucial role in etching, deposition, cleaning, and surface modification.

In a technical sense, plasma is a collection of charged particles, including ions and electrons, that can be manipulated to perform a range of operations. Oxford Instruments specializes in the development of advanced plasma sources and equipment that allow for precise control of these environments to meet specific industrial and scientific needs.

The Role of Plasma Technology in Industry

Plasma technology is central to several industries, particularly in sectors that require precise surface treatments and material manipulation. Industries such as semiconductor manufacturing, aerospace, automotive, and even healthcare benefit significantly from the capabilities provided by Oxford Instruments Plasma Technology.

Semiconductor Manufacturing

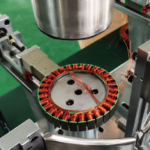

In semiconductor manufacturing, plasma technology is used extensively in processes like etching, deposition, and cleaning. The semiconductor industry relies on plasma to create intricate microstructures on silicon wafers, which are critical for the production of integrated circuits. Oxford Instruments offers specialized tools that enable these processes with high precision, ensuring the creation of reliable and efficient components for electronic devices.

Material Science and Surface Engineering

The ability to modify the properties of materials at a microscopic level is another area where plasma technology excels. Oxford Instruments’ equipment is used in material science for coating and modifying surfaces to enhance their performance. Plasma is used to create thin, durable coatings that increase wear resistance or to etch detailed patterns on surfaces for various applications.

Medical and Biotechnology Applications

Plasma technology also has significant potential in medical and biotechnological fields. From sterilizing equipment to enhancing the biocompatibility of medical implants, plasma treatment provides non-invasive ways to modify the properties of materials. Oxford Instruments’ plasma systems are leveraged to ensure high-quality results in applications such as sterilization, surface treatment of implants, and even the creation of biocompatible coatings.

How Oxford Instruments Plasma Technology Works

The core of Oxford Instruments Plasma Technology lies in its innovative plasma sources and systems, which are designed for highly controlled environments. Let’s explore some of the key processes involved in plasma technology and the mechanisms at play.

Plasma Etching and Deposition

Plasma etching is one of the most common applications of Oxford Instruments Plasma Technology. During etching, plasma is used to remove specific material from the surface of a substrate. This is crucial in industries like semiconductor manufacturing, where precise patterning of materials is required.

Deposition, on the other hand, is the process of applying thin films or coatings to a surface using plasma. This process is vital in creating layers for electronic components or enhancing the properties of materials. Plasma deposition systems from Oxford Instruments offer high precision and uniformity, enabling consistent quality in end products.

Plasma Cleaning and Activation

Another area where Oxford Instruments Plasma Technology stands out is in plasma cleaning and activation. In cleaning, plasma is used to remove unwanted contaminants from surfaces, ensuring that the materials are clean and ready for further processing. Activation, on the other hand, involves altering the surface properties of materials to improve adhesion, wetting, and bonding characteristics.

The Importance of Precision in Plasma Systems

The precision of plasma treatment is essential, particularly when dealing with delicate materials or intricate designs. Oxford Instruments Plasma Technology places great emphasis on providing systems that offer high levels of control over plasma parameters such as pressure, temperature, and gas composition. These factors are critical in achieving the desired outcome, whether that’s in the development of advanced electronic devices, the production of medical implants, or the creation of durable coatings for industrial tools.

By providing sophisticated control over the plasma environment, Oxford Instruments ensures that manufacturers and researchers can achieve the exact specifications they need. This precision is what sets Oxford Instruments apart from many other players in the plasma technology field.

Advancements and Innovations in Oxford Instruments Plasma Technology

As a leader in the field, Oxford Instruments Plasma Technology is always pushing the boundaries of what is possible with plasma science. Some of the key innovations include:

Improved Plasma Source Designs

Oxford Instruments has made significant strides in the development of plasma source designs, offering systems that generate high-quality plasma with uniformity and repeatability. These innovations are vital in improving the reliability of processes and ensuring that results meet stringent industrial standards.

Compact Systems for Laboratory Use

In addition to large-scale industrial systems, Oxford Instruments also provides compact plasma systems suitable for laboratory settings. These systems are ideal for research applications, where scientists need to explore new materials or processes in a controlled environment. The versatility and scalability of Oxford Instruments Plasma Technology make it ideal for both large manufacturers and research institutions.

Integration of Plasma Systems with Other Technologies

Another innovation that Oxford Instruments has pioneered is the integration of plasma technology with other advanced techniques, such as ion beam technology and atomic layer deposition. These hybrid systems offer enhanced capabilities, enabling researchers and manufacturers to perform complex tasks that were previously impossible with standalone technologies.

Applications Across Multiple Sectors

Oxford Instruments Plasma Technology is not limited to one industry; its applications span a broad range of fields. Here’s a closer look at how it is used across various sectors:

Aerospace

In the aerospace industry, plasma technology plays a vital role in coating materials, improving surface properties, and even cleaning components used in spacecraft. Oxford Instruments offers specialized equipment for processing materials that must withstand extreme conditions in space.

Automotive

The automotive industry benefits from plasma technology for processes like coating engine parts, improving fuel efficiency, and enhancing vehicle performance. Oxford Instruments Plasma Technology allows for the precise modification of material properties to meet the demanding needs of the automotive sector.

Electronics and Telecommunications

The electronics industry relies heavily on plasma technology for the production of microelectronics, including semiconductors and sensors. Plasma is essential for processes such as etching circuit patterns and depositing thin films. Oxford Instruments’ plasma systems help ensure that electronic devices perform at their best.

Environmental and Waste Treatment

Plasma technology also has applications in environmental management, such as waste treatment and water purification. Oxford Instruments provides solutions that use plasma to break down harmful chemicals and pollutants, offering sustainable solutions for industries and municipalities alike.

The Future of Oxford Instruments Plasma Technology

The future of Oxford Instruments Plasma Technology looks promising, with the company continually innovating to address new challenges and expand the range of applications. As industries evolve and new materials and processes are developed, Oxford Instruments remains at the forefront of plasma technology, providing solutions that push the boundaries of what is possible.

One exciting area of growth is the application of plasma technology in nanotechnology and biotechnology. As research in these fields accelerates, the demand for precise, high-quality plasma systems is expected to grow, and Oxford Instruments is poised to meet that demand with next-generation solutions.

Conclusion

Oxford Instruments Plasma Technology is a powerful tool that has revolutionized many industries by providing precise, controlled plasma environments for a variety of applications. From semiconductor manufacturing to medical technology, the ability to manipulate plasma with such accuracy has opened up new possibilities in science and industry. As a leader in this field, Oxford Instruments continues to drive innovation and provide cutting-edge solutions that help industries achieve their goals.